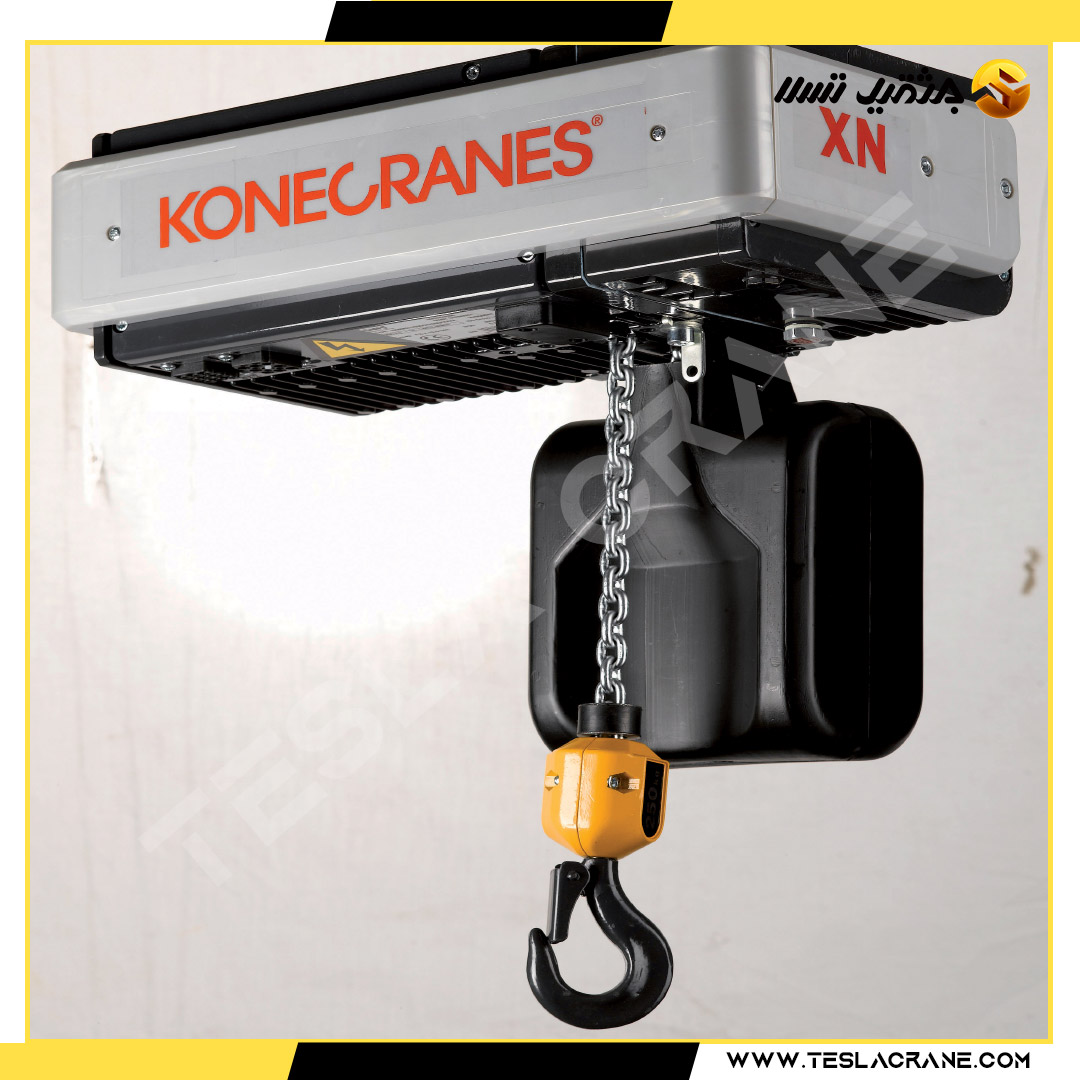

In chain hoists, the connection between the hook and the body of the machine is a chain, and due to the large space of the chain, the construction of this hoist is limited in capacity and height.

Chain lifts are a cost-effective and affordable option for small spaces that can be provided manually, electrically, inflatable. Chain lifts are commonly used in light industry. In chain hoists, the lift is done by pulling the chain by the gears.

Chain hoists can be introduced as an economical hoist because they have relatively less maintenance and are also cheaper than tow rope hoists. These reasons have made these forklifts more popular in small industries than towed wire hoists.

Electric chain hoists can be equipped with various equipments so that we can create better performance for the user. By using a load limiter, in addition to protecting the mechanical parts of your forklift, you can also prevent overload capacity. The flow control unit connects to the high and low speeds and controls them. Electric chain hoists come standard with a steering wheel that has two buttons, four buttons and six buttons, and one button for the number of crane movements. Emergency radio control can be replaced due to cable suspension and possible damage during production.

Another piece of equipment that can be attached to a chain hoist is hanging scales. Using the hanging scales, you can measure the load, and when there is no need to measure the load, you can perform the production operation by removing the hanging scales. Also in European chain hoists, these hoists are equipped with an internal inverter system.

Inverters prevent mechanical stress when moving. The chain lift inverter ultimately ensures simplicity, proper operation and safety. Crane inverter is specially designed for industrial applications and meets all the requirements of the industry.

Tesla Crane Company is able to supply a variety of chain hoists in various brands such as Stahl (Stahl), Kone crane (Kone Crane) and Samsung (Samsung) and others.