Air hoists in the industry are also known as air hoists. It is very useful for jobs that require safe forklifts for industries that do not need electricity. Pneumatic hoists use chain pressure to allow the chain or tow wire to move.

The mechanism of power generation in pneumatic hoists includes cylinders and pistons (compressors). An engine or pump moves the piston inside the cylinder, increasing the internal air pressure and causing the cylinder to move along the piston axis.

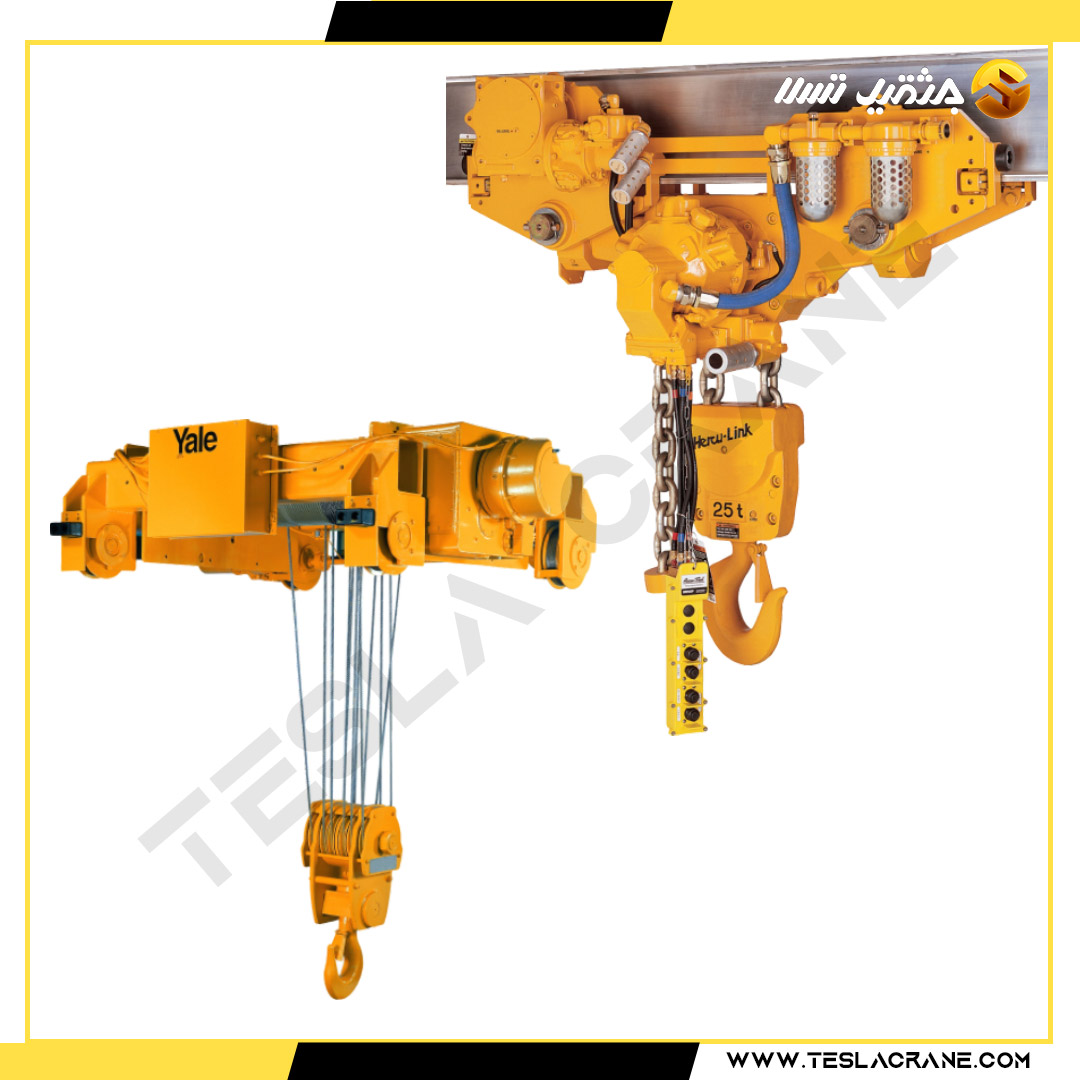

Pneumatic lifts are made of important parts such as compressors, filters, dryers and pipes, hoses and fittings. Pneumatic hoists are very similar in characteristics to electric chain hoists. It is in their power supply that pneumatic hoists differ from the feed air, while electric chain hoists depend on energy sources. One of the most important advantages of chain hoists is that it can be continued in production environments.

Pneumatic chain hoists have variable hoisting speed, the more the user presses the button, the more air passes through the valve and the hoists goes up or down in the useful direction.

Pneumatic forklifts are controlled by the steering wheel. Since pneumatic forklifts do not require electricity, they are a suitable option for explosion-proof environments (ATEX). They are a cost-effective solution compared to electric chain hoists. The use of pneumatic lifts in various industries such as automotive, oil and gas, etc. are a priority.

Major manufacturers of JDN, Yale, Atlas copco, ingersoll Rand Neuhavs JD pneumatic hoists can also be used underwater with special design.

The compressed air force is connected to the air lift through the pipes and directs the production operation with maximum safety.