بالابرهای بادی در صنعت به بالابرهای پنوماتیک نیز معروف هستند. برای مشاغلی که نیاز به بالابرهای قابل اعتماد برای صنایعی که نیاز به برق ندارند بسیار ...

بالابرهای بادی در صنعت به بالابرهای پنوماتیک نیز معروف هستند. برای مشاغلی که نیاز به بالابرهای قابل اعتماد برای صنایعی که نیاز به برق ندارند بسیار مفید است. بالابرهای بادی با استفاده از اختلاف فشارهوا حرکت زنجیری یا سیم بکسل را ممکن می سازد.

مکانیسم تولید نیرو در بالابرهای بادی شامل سیلندر و پیستون (کمپرسور) می باشد. یک موتور و یا یک پمپ، پیستون را در داخل سیلندر حرکت می دهد و فشار داخلی هوا را افزایش داده و باعث حرکت سیلندر در امتداد محور پیستون می گردد.

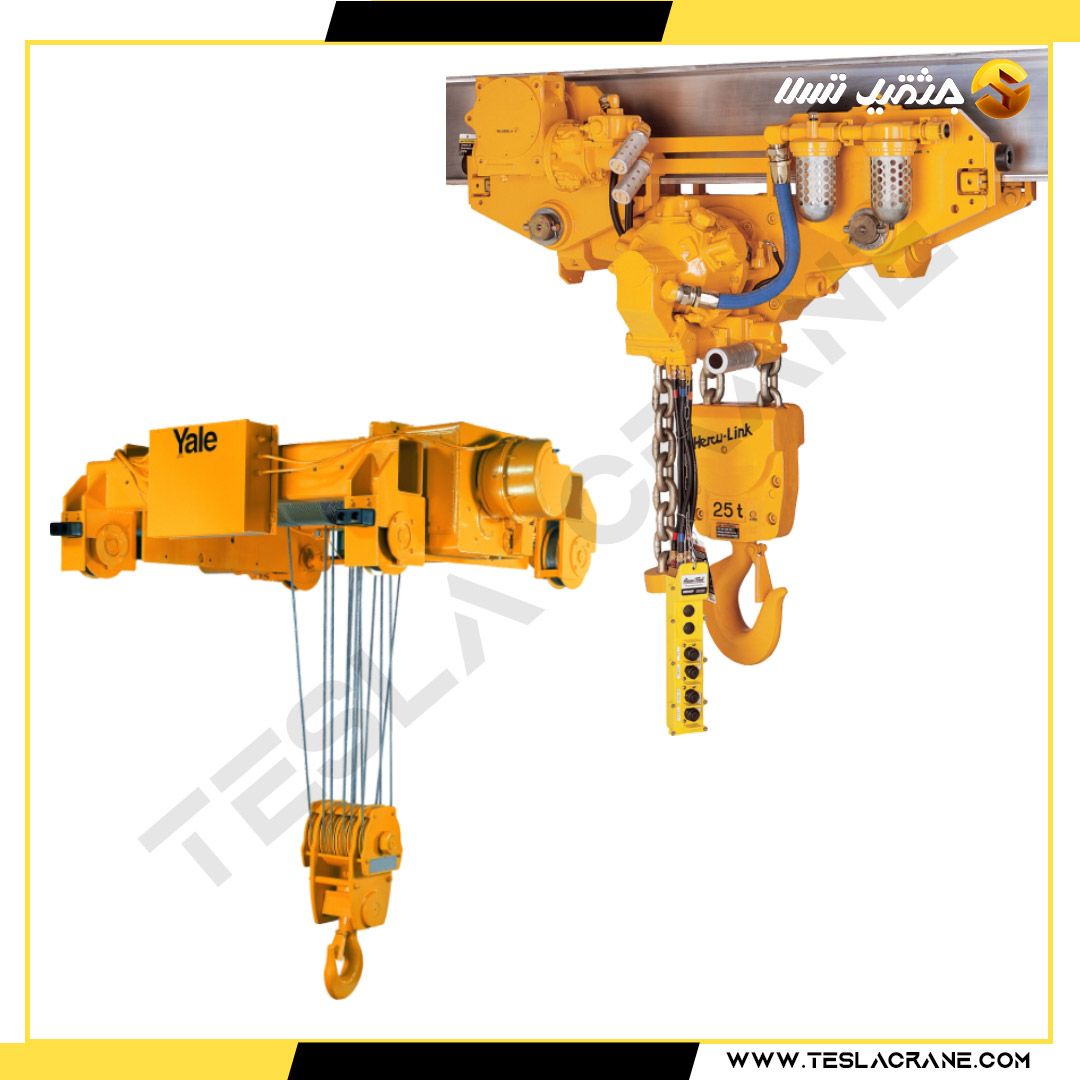

بالابرهای بادی از قسمت های مهمی مانند کمپرسور ، صافی، خشک کن و لوله ها، شلینگ ها و اتصالات تشکیل شده اند. بالابرهای بادی یا پنوماتیک از نظر ویژگی بسیار شبیه به بالابرهای زنجیری برقی می باشند. تفاوت آن ها در تغذیه آن هاست که بالابرهای پنوماتیک از هوای فشرده تغذیه می شوند در حالی که بالابرهای زنجیری برقی به منابع الکتریکی وابسته هستند. یکی از مهمترین مزیت های بالابرهای بادی این است که می توان بصورت مداوم در محیط های تولیدی از آن ها استفاده کرد بدون نگرانی از گرم شدن بیش از حد این امکان در بالابرهای زنجیری وجود ندارد و این بالابرها در عملکرد بیش از ظرفیت دچار مشکل می شوند.

بالابرهای زنجیری بادی دارای سرعت بالابری متغیر هستند، هرچه کاربر دکمه را بیشتر فشار دهد هوای بیشتری از دریچه عبور می کند و بالابر در مسیر مفید بالا یا پایین می رود.

بالابرهای بادی بوسیله کلید فرمان کنترل می شوند ازآنجایی که بالابرهای بادی نیاز به برق ندارند یک گزینه مناسب برای محیط های ضد انفجاری (ATEX) می باشد. در مقایسه با بالابرهای زنجیری برقی یک راه حل مقرون به صرفه می باشند. استفاده از بالابرهای بادی در صنایع مختلفی مثل خودروسازی، نفت و گاز و ... در اولویت هستند.

تولیدکنندگان عمده بالابرهای بادی JDN, Yale, Atlas copco, ingersoll Rand Neuhavs JD هم چنین در یک طراحی خاص می توان بالابرهای بادی را در زیر آب نیز استفاده کرد.

نیروی هوای فشرده از طریق لوله ها به بالابر بادی متصل شده و با بیشترین ایمنی عملیات تولیدی را رهبری می کند.

از مزایای این بالابرها:

1. طراحی جمع و جور و سبک

2. عملکرد فوق العاده برای عملیات که نیاز به سرعت بالا دارد.

3. استفاده از این بالابرها در مکان هایی که خطر احتراق زیاد است، مانند کارخانه های تولید مواد شیمیایی

4. دارای محفظه فولادی چدنی با استحکام بالا برای دوام بیشتر

5. دارای ترمز خودکار دیسک ایمن

6. دارای سیستم توقف اضطراری

7. کاربرد در صنایع مختلف

8. حرکت در سرعت های مختلف

9. ایمن در برابر خطر انفجار

10. کاربرد در صنایع نفت و گاز

11. کاربرد خطوط مونتاژ

12. کاربرد در ریخته گری

13. کاربرد در صنایع شیمیایی

14. مهندسی مکانیک

15. صنایع غذایی، دریایی، معادن و ....