This part is an electrical mechanical part that cuts or destroys the moving parts of the device. This part is called the brake. Items of this part: frame, brake, controller. Some brakes are adjusted and equipped automatically.

Brakes used Cranes (longitudinal / transverse / hook) must have brakes to stop at the desired location. The brakes are both electric and mechanical. In electric brakes, the pad is separated from the plate by a magnetic coil and makes the movement, and in the time of non-electricity, it is attached to the plate by brackets and brakes. In mechanical (conical) brakes, the pad is stuck inside the conical bowl and when the engine starts to move with centrifugal force, the pad separates from the bowl and allows movement.

The crane brake provides work safety. In forklifts, the brakes can stop or control the goods and loads that are being transferred at any height and volume. The brakes can reduce the speed or generally reduce the speed to zero and stop the movement. To do this, the piece needs kinetic and potential energies that receive these energies during the work process and use them thermally.

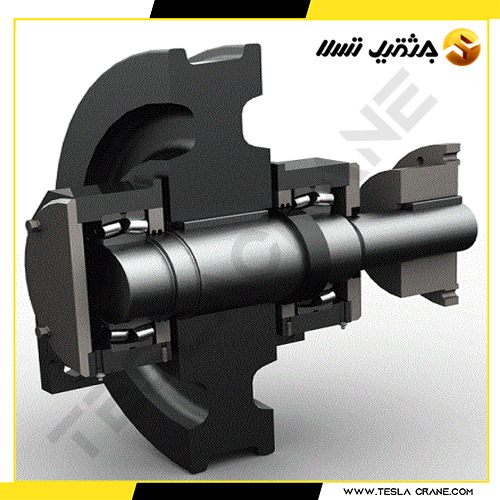

In this type of brakes, which are commonly used in Damag and Bulgarian (Podem) cranes, compared to the type of tractor structure, which is conical (conical), the end of the rotor shaft, which has a thousand spines, the brake pulley through these spines to The shaft is connected. There is a brake pad on this pulley and it is connected to the end cap of the engine and this connection causes the brake.

This type of brake works on the basis of induction (magnetism) and causes the crane motor to stop or slow down. Inside the brake magnet is a coil with a high ohm value that can not be measured even with ordinary ohmmeters. When these coils are connected to the power supply, their magnetism is activated and the disk in front of the magnet is attracted to it, and by releasing the disk from the brake pad, the motor starts to move. In case of power failure of the disc, which is caused by the springs on the magnet by pressing on the pad, they cause the crane motor to stop and brake. Forms of this type of brakes: brake magnet / magnet disk / brake pad / spring / rectifier

Shoe brakes are mostly used in lifts and winches. The place of installation of shoe brakes is on the gearbox. Which is installed by means of a circular coupling with friction surface.

When electricity enters the motor, the motor shaft is released through the applied pressure and the motor shaft is released upwards, and this movement causes the shoes to be released from the coupling. In this case, the brake is free and the engine turns and runs easily. In the crane industry, this type of brake is called the second brake. When the power is cut off, the shoes are connected to the coupling by means of strong springs that are used and the engine is stopped.